It's one of those things with favourite tools. The choice is huge, each item is available in ten different sizes, colours and shapes and for different applications. What you only had to think about for clothing 10 years ago, you now also have to think about for tiling tools - especially tile cutters. Technical progress is rapid and does not stop at the tiling trade.

Read more ...

How do you recognise a good tile cutter?

Nowadays, there are hundreds of different tile cutter models in every conceivable shape and made from all kinds of materials. From aluminium to plastic, everything is included. In general, however, a distinction is made between manual tile cutters and electric tile cutters.

Hand tile cutter - Structure

The basic construction of a manual tile cutter is the same for every model: there is a base plate made of robust material (wood, metal, plastic) for placing the material to be cut, over which a guide rail is mounted, which allows a cutting carriage with an integrated cutting wheel to slide over the material to be cut and thus score it. The tile is then broken along the scored cut using the (usually) integrated breaking device.

Electric tile cutter - Structure

Similar to a manual tile cutter, an electric tile cutter also has a support plate with a mounted guide rail. In this case, however, a motor is installed on the device, which drives a (preferably) diamond cutting disc that cuts the material with a single cut.

What should I look out for when buying a tile cutter?

When choosing your tile cutter (whether manual or electric), you should always pay attention to the materials used. Tile cutters that are largely made of plastic and have a very low weight are not suitable for larger formats and thick tiles in particular. The risk of tipping over during the cutting process is extremely high here. A plastic base plate also runs the risk of warping over time. This can also happen due to impacts or improper transport. The result is crooked cuts and broken tiles. It is better to choose a tile cutter made of aluminium, wood or metal. All of these materials are robust, durable and resistant to warping. With wooden board cutters, you should make sure that the support plate is glued waterproof to prevent warping. A good manual tile cutter has, in addition to a distortion-free base frame, accessories such as a side arm, measuring scale, stop angle and breaking device. Fold-out side stabilisers not only increase the stability of the tile cutter, they also allow large tile formats to be placed safely on the tile cutter without falling off. An easy-to-read, preferably wipe-clean measuring scale with a stop angle is important for making the cut in the right place. This minimises material wear due to incorrect cuts. An integrated breaking device on the tile cutter is practical for breaking the scored material in a single pass. There are various breaking devices. Some work by pressing down the cutting arm, others by placing the tiles on a breaking cone and pressing down the guide rail or a breaking arm. Important: it is essential that you take a closer look at the guide rail and the cutting arm of the tile cutter. The cutting arm should glide smoothly over the cutting rail without faltering or jerking. It should not have any play to the right or left, otherwise there is a risk of an uneven cut. Ball-bearing and simply guided cutting arms usually deliver the best cutting results.

How do you work with a tile cutter?

Using a tile cutter is not rocket science. Nevertheless, after purchasing your new tile cutter, you should always read the manufacturer's operating instructions and follow the important instructions for the machine. If you do not do this and use the tile cutter incorrectly, the manufacturer will not provide any guarantee in the event of subsequent damage to the machine or cuttings or unusually high wear! The cutting results will also not be perfect if the machine is used incorrectly. The tile cutter should always be placed on a firm, level surface. The floor or a stable work table is best suited (highly recommended for back-friendly working). Unfold the side stabilisers and remove any transport locks. Place your tile on the support plate. Using the stop angle and the measuring scale, you can see where you need to place the tile in order to make the cut in the correct position. Now place the cutting arm with the cutting wheel at the start of the tile and press it down by the handle so that the cutting wheel rests on the material. Now guide the cutting arm over the tile. Depending on the tile cutter, you may need to apply more or less, but always the same amount of pressure to ensure that the material is scored evenly. In any case, only run the cutting wheel over the material once, never twice. Always run the cutting arm along the entire length of the tile (do not stop just before the end) and then remove the cutting wheel from the tile surface. Now you can break the tile with a crusher or the integrated crusher on the tile cutter. Use the right amount of force here. Breaking too quickly and forcefully usually causes the material to flake off. If too little force is applied at the beginning, the tile usually only breaks up to the centre and the end of the tile remains whole. Apply constant, correctly dosed pressure right from the start. With a new tile cutter, you should first make a few test cuts anyway to familiarise yourself with how it works.

Which tile cutter is right for me?

Before buying a tile cutter, you should always ask yourself what materials you need to cut and how often you will be using your tile cutter. As tile formats are becoming larger and larger, you should also consider whether or not you want to offer the laying of XXL tiles as a service. In this case, you are definitely on the safe side with a tile cutter with a longer cutting length, as this can also be used to cut normal formats at any time.

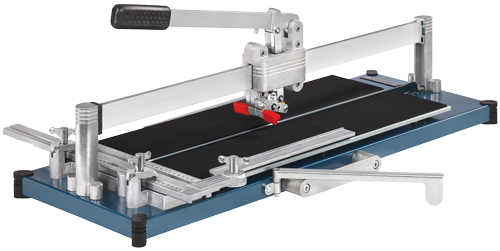

High-Line tile cutter from Karl Dahm

The Karl Dahm High-Line tile cutter offers a 100% straight cut in all cutting lengths. From a cutting length of 630 mm to 1850 mm, the High-Line is available in many different versions and for every material. The ball-bearing mounted cutting arm runs safely and smoothly along the unique guide rail. The High-Line tile cutter is available with both a robust wooden support plate and a modern compact plate. The integrated "High-Line" breaking device is available as an option, allowing you to break even the thickest materials perfectly and safely. The High-Line tile cutter is the perfect tile cutter for professionals.

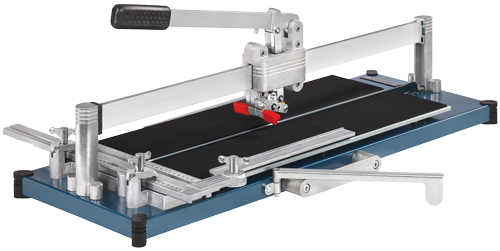

Tile cutting and crushing machine

The tile cutting and crushing machine from Karl Dahm is the perfect companion on the construction site. If you need your tile cutter for quick cuts from time to time, this tile cutter is the right one for you. With its sturdy metal base construction, it reliably cuts almost all materials. The tile cutting and breaking machine is available in cutting lengths from 630 to 1830 mm. You are sure to find the right tile cutter model in our tile cutter section.

If you have any questions, simply give us a call and our specialist advisors will be happy to help you.

The satisfaction of our customers is important to us!

Tel.: +49 8667 8780

E-Mail: info@dahm-werkzeuge.de

Let us convince you of our tile cutters and their quality!